Nội dung bài viết

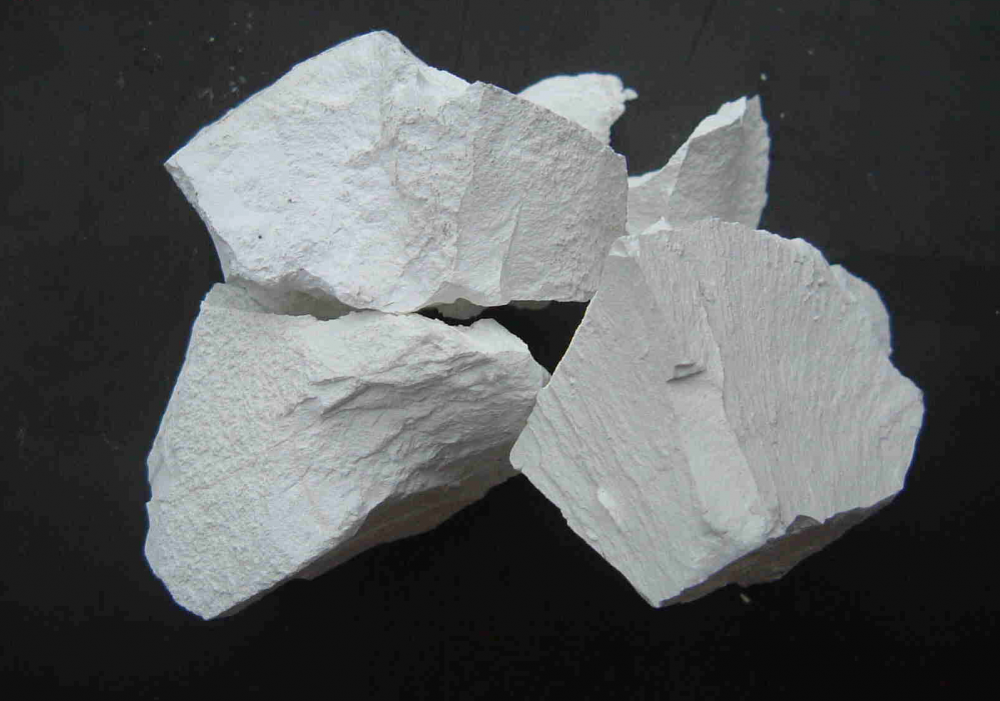

Calcium oxide CaO, also known by other names such as calcium, quicklime or calcined lime, is a white, caustic and alkaline crystalline solid at room temperature. It is a commercial product containing magnesium oxide, silicon oxide, smaller amounts of aluminum oxide and iron oxide, widely used in life, especially in the fields of metallurgy and environmental treatment. In India, before people discovered soap, it was mixed with sand and used to clean the body. So calcium oxide How is it produced, what specific applications are there? . The article below will answer those questions for you

Overview of Calcium Oxide

What is calcium oxide CaO? Quicklime. Physical and chemical characteristics

Calcium oxide CaO is also known by other names such as calcium, quicklime or calcined lime.

|

Molecular formula |

High |

|

Physical state |

Crystalline solid |

|

Color |

White |

|

Nature |

It is caustic and alkaline |

|

Ingredient |

In addition to CaO, quicklime also contains impurities such as Magnesium oxide, Silicon oxide, Aluminum oxide, Iron II oxide. |

|

Molar mass |

56.1 g/mol |

|

Expansion coefficient |

0.148 |

|

Boiling temperature |

2850oC ( 3123 K) |

|

Melting temperature |

2572oC ( 2845 K) |

|

Specific gravity |

3.3- 3.4 x 103 kg/m3 |

|

Solubility |

Soluble in water |

|

Crystal structure |

Face-centered cubic |

|

Melting temperature |

2572oC ( 2845 K) |

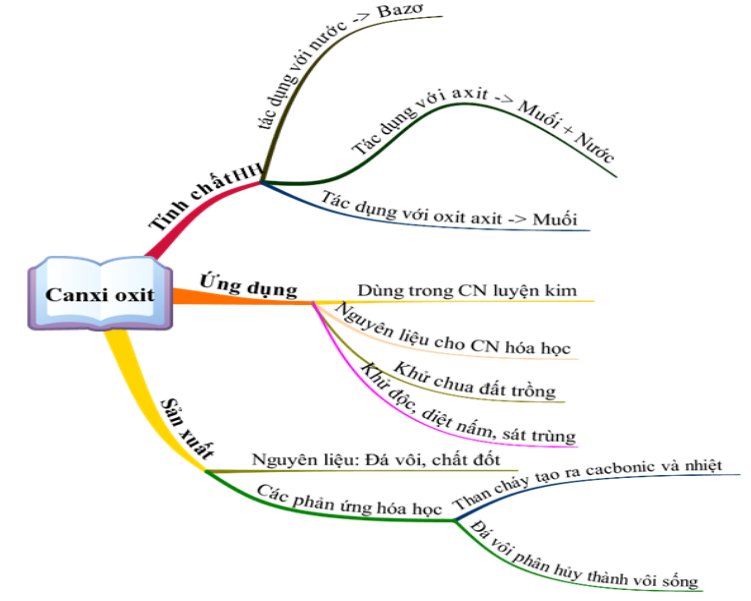

Calcium oxide is a basic oxide so it has all the properties of a basic oxide.

- Reacts with water

CaO + H2O → Ca(OH)2

- Reacts with acids to form salt and water

CaO + 2HCl → CaCl2 + H2O

- Reacts with acid oxides to form salts

CaO + CO2 → CaCO3

The reaction occurs when quicklime is added to water

CaO + H2O → Ca(OH)2

Calcium oxide – Quicklime production process

Raw materials used to produce quicklime are rocks rich in calcium carbonate minerals, mainly limestone. There are also some other types such as coral stone and dolomite stone (clay content less than 6%).

Quicklime production line

Crush the stone into small lumps of 10-20cm in size before heating in a furnace with high temperatures from 900-1100oC. The fuel used is wood, oil, natural gas, etc. The reaction occurs as follows:

Burning coal produces CO2 gas and radiates a lot of heat

C + O2 → CO2

The heat generated decomposes the limestone

CaCO3 ↔ CaO + CO2 – Q (calorific)

This is a reversible reaction. Therefore, if you want to increase the quality of lime, you need to push it in the right direction by creating ventilation in the lime kiln so that CO2 gas can escape easily.

Manual lime production furnace

Note:

If the stones being burned are of irregular size, the phenomenon of quicklime and burnt lime can easily occur.

- If large rocks are heated, the calcium carbonate will not completely convert to calcium oxide, causing the finished product to be of poor quality, with many stones and less flexibility.

- With small sized rocks or too high a temperature in the kiln, the calcium oxide produced will react with clay impurities to form a very hard calcium silicate and calcium aluminate colloidal film. They cover the lime particles, making them difficult to hydrolyze in water. Lime absorbs a lot of water, increasing its volume, causing the structure to pit and crack.

Criteria for evaluating the quality of quicklime

The quality of lime depends on the calcium oxide content.

Quicklime

Criteria for assessing lime quality:

- Lime activity: Depends on calcium oxide and magnesium oxide content. The larger the quantity, the greater the lime mortar output and vice versa.

- Quenching temperature (highest temperature of the quenching process) and quenching time (calculated from the time lime is added to water until the boiling temperature reaches the highest level): The greater the amount of heat released when lime is quenched, the longer the quenching time. In short, the purer the lime, the more calcium oxide it contains. The output of lime mortar produced will be large.

- Lime yield: The greater the amount of crushed lime, the better the quality of lime. They depend on calcium oxide content, temperature, and quenching time.

- Amount of grit (unslaked lime particles in lime mortar): The amount of grit is the ratio of the mass of grit to the mass of quicklime (remaining particles on the 124-hole sieve/cm2), calculated in %. The smaller the amount of grit, the more lime can react with water, and the more lime mortar produced.

- Fineness of quicklime powder.

The finer the quicklime powder, the easier it is to completely react with water, forming more lime mortar. Basic criteria for assessing the quality of lime are prescribed according to TCVN 2231 – 1989.

|

Target name |

Lump lime and crushed lime |

||

|

Type I |

Type II |

Type II |

|

|

Lime sintering speed (minutes) |

|||

|

I'm fast (lower) |

10 |

10 |

10 |

|

I'm average (lower) |

20 |

20 |

20 |

|

I'm slow (older) |

20 |

20 |

20 |

|

Magnesium oxide content (%) (lower) |

5 |

5 |

5 |

|

Total active (CaO+MgO) content (%), (greater than) |

88 |

80 |

70 |

|

Fineness of slaked lime, l/kg, (larger) |

2.4 |

2.0 |

1.6 |

|

Unslaked particle content of lump lime (%), (lower) |

5 |

7 |

10 |

|

Fineness of lime powder (% ), (lower) |

|||

|

On sieve 0.063 |

2 |

2 |

2 |

|

On 0.008 sieve |

10 |

10 |

10 |

Distinguish between quicklime – slaked lime (powdered lime) – limestone

1. Quicklime

Quicklime, also known as Calcium Oxide, is a chemical compound with the formula CaO. They have the following characteristics to identify: They have the form of solid crystals, white powder or lumps.

2. Slaked lime

Slaked lime, also known as Calcium hydroxide, is a chemical compound with the formula Ca(OH)2. They are colorless crystals or white powders, and are obtained when calcium oxide reacts with water.

Slaked lime is widely used in industry in various fields such as water treatment, cleaning, construction, fertilizer production, etc.

3. Limestone

Limestone is known as a sedimentary rock, with the main chemical composition being the minerals calcite and aragonite.

Limestone is rarely in pure form and is often mixed with impurities such as chert, silica or igneous rock as well as clay, mud, sand, bitumen… Therefore, it has all colors from white to dark brown. ash, light blue, yellow and even dark pink or black…

Application of Calcium Oxide

Lime is commonly used in two forms: ripe lime and quick lime powder.

1. Ripe lime

Ripe lime is lime that has been slaked (ie put quicklime in water).

CaO + H2O → Ca(OH)2 + Q

The reaction releases a lot of heat, the water bubbles up, and if you are not careful, splashing it can cause severe burns. The rising smoke is white because it contains calcium hydroxide particles.

Lime powder

Depending on the amount of water used to slake the lime, we divide it into the following 3 types of ripe lime:

- Ripe lime powder: The amount of water used is equivalent to 70% of the lime weight because the water is evaporated due to the heat generated from the reaction. The volume of lime powder ranges from 400- 450kg/m3.

- Puree lime: The amount of water used is greater than 70% of the lime weight. The product then formed is a thick mortar in which calcium hydroxide accounts for about 50%, the remainder is water. The volume of crushed lime ranges from 1200-1400kg/m3.

- Milk lime: The amount of water used is greater than the amount of water used for pureed lime. The resulting product is then a thick mortar in which calcium hydroxide accounts for less than 50%, the remainder is water.

2. Quicklime powder

To produce quicklime powder, lime lumps are crushed until they become fine powder. They are then stored in sealed bags and used like cement.

The advantages and disadvantages of ripe lime and quick lime powder

|

Ripe lime |

Quick lime powder |

|

|

Advantage |

Easy to store and use |

– Solid and fast. – High bearing strength due to taking advantage of the heat released when lime is quenched to create a silicate reaction. – Limit the harmful effects of grit, without wasting time |

|

Disadvantages |

– Low bearing strength. – It is difficult to limit the harmful effects of old fire grains, so it is necessary to carefully screen these grains before use. |

– Difficult to preserve because they easily absorb moisture, reducing the quality of lime. – For production, a large amount of equipment is needed, and the lime dust created has a negative impact on the health of workers. |

Application of quicklime powder:

Proportion of lime use by industries

|

Application field |

Proportion |

|

Steel, metallurgy |

31 |

|

Paper |

5 |

|

Light powder |

6 |

|

Environmental treatment |

34 |

|

Build |

10 |

|

Other industries (chemical, food,…) |

14 |

- In the construction industry such as housing, schools, public works, etc. milk lime, pureed lime or quicklime powder are commonly used.

People mix lime, sand, cement, and water in certain proportions to create a mortar and plaster mixture. Mortar containing lime has high adhesion because the loss of water when dry causes calcium hydroxide to crystallize and at the same time, carbon dioxide in the air causes carbonation of lime, making the mixture solid.

Lime is used to mix mortar in construction

- Producing silicate bricks, glass, covering ceilings and walls, and being a lignin-dissolving agent in the paper industry.

- Used in the metallurgical industry and as a raw material for the chemical industry, to remove slag impurities in the metal and alloy production industry thanks to its ability to react with silicate salts.

- In the wastewater treatment industry, quicklime acts as a softening, flocculating, and recovery additive to remove inorganic and organic impurities containing phosphate. Quicklime is used to dissolve lignin in the process. paper manufacturing industry,…

- Clear lime water is used to soak squash, carrots, etc. in making jam, making them crispier.

Prepare jams with clear lime juice

- Lime used for aquaculture has the effect of reducing alum, disinfecting, killing fungi, detoxifying the environment, reducing pH to help reduce acidity, and improve soil.

Powdered lime is used to improve soil

Clean the environment with lime powder

-

Used to purify citric acid, glucose, dyes.

-

In ceramic production:

Used as a melting aid for medium and high firing enamels at a temperature of 1100oC, helping the resulting product have higher hardness, less scratches, retain enamel color and be able to withstand acids.

Reduces viscosity for enamels with high silica content.

Enhances the hardness of ceramic glaze

- Calcium oxide has strong hygroscopic properties so it is used to dry many substances.

Store lime properly

- Don't leave it too long to avoid the lime reacting with water vapor in the air, reducing the quality. So I should grind it as soon as possible or grind it finely and store it in a sealed bag.

- Pureed lime needs to be soaked in holes with a layer of sand or water on top, 10 – 20 cm thick to prevent contact of lime with carbon dioxide in the air. The reaction occurs as follows:

Ca(OH)2 + CO2 → CaCO3 + H2O

- If calcium carbonate petrifies lime, it will lose quality and become less flexible, reducing its ability to bond.

Trường Chu Văn An- Address to buy quality calcium oxide in Hanoi

Established in 2000, after nearly 20 years of construction and development, Trường Chu Văn An has risen to become a leading company in importing and distributing chemicals, tools, and scientific and technical equipment in Vietnam. .

With the criteria of “Cooperation for mutual development” and the orientation of “Continuous improvement, constantly improving product quality”, Trường Chu Văn An has always made efforts in training human resources, improving facilities, build brand reputation, become a reliable partner for many large domestic and foreign companies and agents as well as customers in the market from North to South.

When buying Calcium Oxide at Trường Chu Văn An, you can be completely assured about product quality and price. Not only that, the company's delivery staff will help products reach customers quickly and accurately as scheduled.

Hopefully, the above article from Trường Chu Văn An will help readers understand Calcium oxide and its applications in life. Customers interested in our products please contact directly to phone number 0826 010 010 for the best advice and support. Thank you very much!

See more:

- Calcium hydroxide- Characteristics, preparation process and common applications

- Methods of preparing acetic acid CH3COOH and applications of acetic acid

Nội dung được phát triển bởi đội ngũ truongchuvananhue.edu.vn với mục đích chia sẻ và tăng trải nghiệm khách hàng. Mọi ý kiến đóng góp xin vui lòng liên hệ tổng đài chăm sóc: 1900 0000 hoặc email: hotro@truongchuvananhue.edu.vn