Nội dung bài viết

The market today has a variety of electrical cables, of which multi-core electrical cables are still the most popular choice thanks to their flexibility, variety of types, designs and compatibility with many systems. Learn in detail about the characteristics and classification of multi-core electric wires in the following article.

What is multi-core wire?

Multi-core electric wire is a type of electric cable with 2 or more conductive cores, most of each core is individually insulated with PVC or XLPE with an outer layer of PVC plastic. This wire is flexible, malleable, easy to connect, has high tensile strength and has better thermal conductivity than single-core wire. Thanks to its flexible and durable properties, multi-core electrical wires are the optimal choice for applications requiring high load bearing, frequent movement, bending or installation in environments with complex terrain.

Multi-core electric wire has the following advantages:

- High flexibility: Able to bend to many terrains and easy to adjust and move, so suitable for wall-mounted installation in pipes or applications requiring repetitive motion.

- Performance Guarantee: Gathering 2 or more conductors, the conductor of a multi-core wire has space for electricity to flow safely, minimizing the amount of heat generated due to the Joule phenomenon. Thereby ensuring the power transmission performance of the wire even in applications with high load currents.

- Reduce surface effects: Multi-core wires are preferred for use in alternating current to reduce skin effect – a phenomenon that causes current to concentrate in the wire sheath, which causes energy loss.

However, this type of electric wire also has some disadvantages such as:

- Easily corroded: Multi-strand twisted copper wires are more susceptible to corrosion than single-core wires, causing electrical conductivity and wire life to be reduced. Therefore, when installing outdoors, priority should be given to choosing insulating materials such as TPE, rubber, PUR,…

- Low current conductivity: The space between the conductive core of a multi-core cable reduces the current-conducting ability compared to a single-core type with the same cross-section.

- More pressure drop: Multi-core wires can cause signal interference in high-frequency communications applications, with attenuation rates ranging from 20-50%. In addition, voltage drops in multi-core cables will occur more often than in single-core cables, especially when transmitting current over long distances.

Structure of multi-core electric wire

Multi-core electric wires have a basic structure consisting of 3 main components: conductor core, insulation layer and protective shell.

- Conductive core: A collection of many conductive cores, each core consists of many copper or aluminum strands twisted together, covered with a separate insulation layer to increase durability and safety.

- Insulation class: The main material is PVC or XLPE plastic, each core will use a different insulating color to facilitate the connection process.

- Protective shell: Usually black in color, the main material is PVC, which is responsible for protecting the core from mechanical impacts, environmental factors or rodent bites.

Many types of multi-core electrical wires are popular on the market

Electric wires with 2 or more cores are classified as multi-core electric wires. On the market today, there are 4 types of multi-core electrical wires most commonly used: 2-core electrical wires, 3-phase 4-core electrical wires, 3-core electrical wires and multi-core flexible electrical wires.

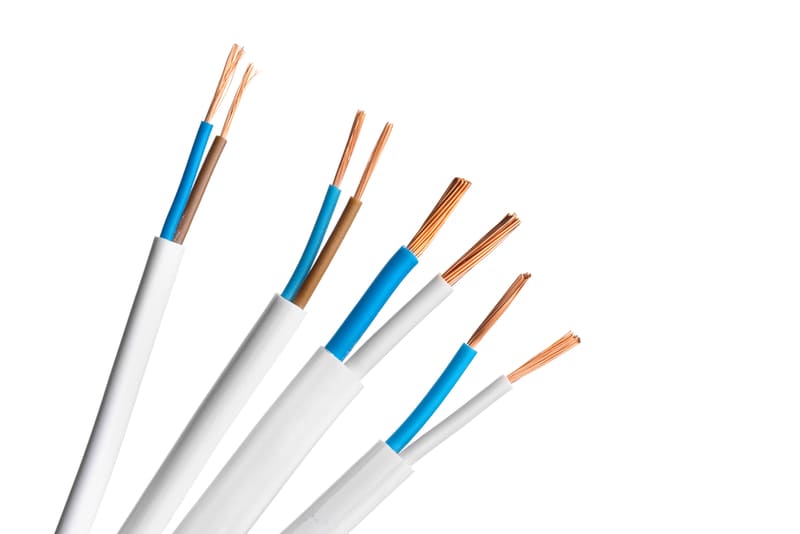

2-core electrical wire

2-core electric wire, also known as flexible double wire (VCm wire), consists of 2 conductive cores placed in parallel, with a separate insulation layer, often widely used in civil or light industrial electrical systems, especially installed at electrical panels, connecting electrical equipment in the home.

This type is flexible, easy to bend, reasonably priced, and is designed for fixed wiring, so it is not suitable for outdoor installation.

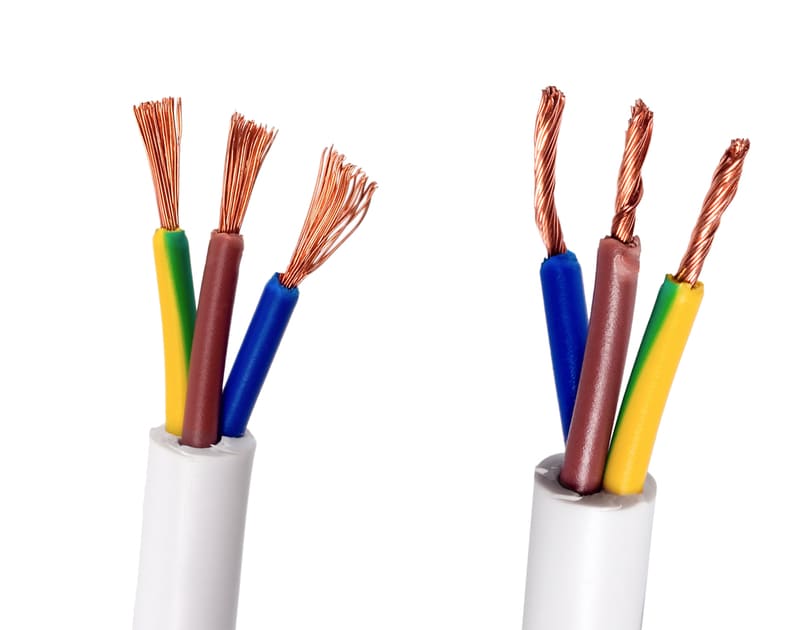

3-core electrical wire

3-core electric wire means the conductor is made up of 3 copper or aluminum cores with an insulating sheath from PVC or XLPE. This is the most popular type of multi-core electrical wire today in balanced 3-phase systems, often used for factories, industrial parks, to transmit power to high-capacity equipment.

In addition, 3-core wires are also used as conductors, connecting many electronic devices in the entertainment field such as cinemas, concerts… Especially, when used with data and AV, 3-core wires also have the effect of minimizing transmission congestion, making them suitable for technology applications or applications with limited space such as aircraft.

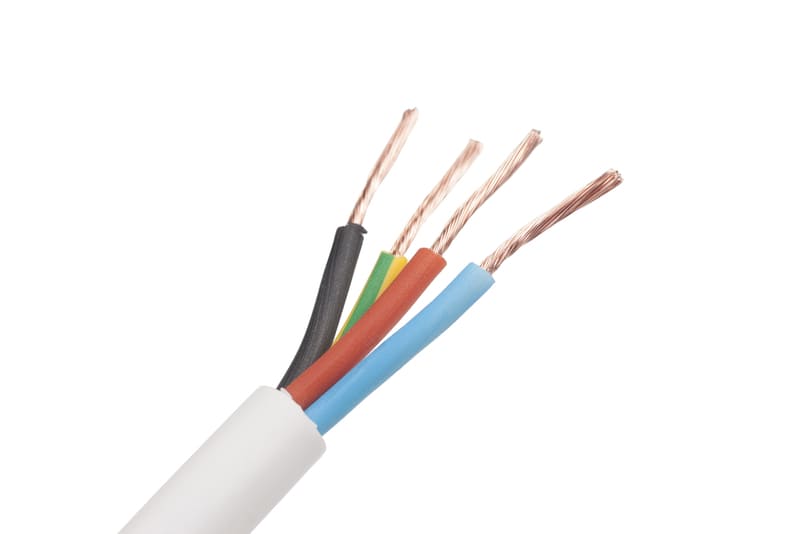

4-core electrical wire

4-core electrical wire is the preferred choice in high-voltage stations or 3-phase 4-core power systems for large capacity equipment. In particular, the 4th wire is the neutral wire, which is responsible for ground fault protection and eliminating the magnetic field in case the current is unbalanced.

4-core electrical wires have the following conventional phase wire colors:

- Phase 1: Red

- Phase 2: White or yellow color

- Phase 3: Blue

- Neutral wire: Black.

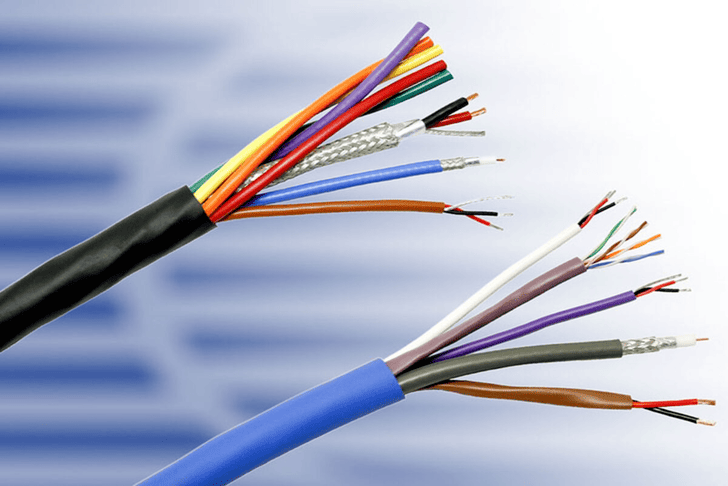

Multi-strand soft wire

This is a type of wire whose conductor is a collection of many small copper or copper-aluminum strands tightly braided together to increase the flexibility of the wire. The advantages of multi-strand soft wires are the ability to conduct electricity well, withstand large loads, be durable during operation and easy to connect, so they are widely used from civil to industrial electricity, especially in factories manufacturing mobile devices, robots and sound systems – signal transmission.

Need to clearly distinguish, single wire also has the form of 1 core with many strands. However, in terms of flexibility and flexibility, multi-strand soft wire is still the optimal choice over multi-strand single-core wire.

Compare multi-core wire with 1 core

Having the same function of transmitting electricity and connecting electrical devices, multi-core electric wires and single-core electric wires have a big difference in the number of conductive cores. This factor determines the difference between the two types of wire in many criteria such as: structure, advantages and disadvantages and applications.

Specifically, how to distinguish multi-core and single-core electrical wires is in the following comparison table:

| Criteria | Multi-core electrical wire | 1-core electrical wire |

| Structure | – From 2 or more conductive cores

– Each conductive core is individually insulated, sharing a protective shell |

– There is only 1 conductive core, covered with 1 insulating layer

– Available in solid core and multi-core 1-core electric wire |

| Advantage | – Has high flexibility and tensile strength, so it is easy to twist and adjust in applications requiring flexible movement

– The space between the conductive fibers helps electricity flow safely through the core, limiting heat generation – Reduce skin effect so voltage loss is reduced |

– Single path design should limit loss of connection during power transmission

– The density of conductive material is greater than that of multi-core wires, so it can carry larger currents – Solid structure, high durability, stable operation even in harsh environments – Lower resistance, resulting in lower voltage drop in long-distance transmission lines |

| Disadvantages | – There is a higher risk of corrosion

– Current conductivity is lower than 1-core wire – Voltage drop is higher than single-core wire |

– Lack of flexibility, limited flexibility, difficult to bend

– Easy to crack when installed in environments with strong vibrations – Surface effect occurs in single wire causing current to concentrate in the wire sheath, reducing transmission efficiency |

| Application | – Provides energy for large capacity electrical equipment

– Connect electronic devices and audio equipment – Data transmission application |

– Transmitting electricity to household appliances in the civil electrical system

– Installed in control cabinets and automation systems – Telecommunications and television systems |

The reason why multi-core electric wires are popular on the market

Multi-core electrical wires are more flexible than single-core electrical wires in both characteristics and applicability. Below are 2 reasons why this type of wire is commonly used in many electrical systems.

Easy to strip, easy to connect

Constructions and projects often have many different terrains, so electrical wiring is unavoidable. This connection must not only comply with correct electrical techniques but also be consistent with the electrical system diagram.

Compared with single-core wire, stripping the protective covering of multi-core wire is much simpler. Just cut off the outer shell, you can easily strip the inner insulating shell. Containing multiple flexible copper or aluminum conductors also allows multi-core wires to connect more tightly.

Stable electrical conductivity, limited heat generation

Multi-core electric wires have a core made of up to 99% pure copper and aluminum, providing stable electrical conductivity. Compared to a single wire with the same cross-section, a multi-core wire has a larger total surface area of the conductive fibers, helping to increase the ability to transmit electricity in harsh applications.

Besides, the space between the conductor cores helps the current move safely, reducing heat generation on the conductor surface, thereby limiting the surface effect, which is one of the causes of voltage loss.

See more: Popular types of electrical wires on the market today

Buy genuine multi-core electrical wires at good prices at Trường Chu Văn An

Trường Chu Văn An is proud to be the official distributor of multi-core electric cables from many reputable brands such as Cadisun, Cadivi, Goldcup, Tran Phu. With nearly 15 years of experience in establishment and development, we are committed to providing 100% genuine and new products, with the most attractive price policies and discount factors on the market.

In addition, with a dedicated, professional customer care team and a team of experts who have many years of cooperation with Electricity units, we can meet consulting requirements and provide power quality solutions from selecting, forecasting and controlling technical issues related to multi-core electrical wires suitable for each project.

Customers who want to buy multi-core electrical wires from Trường Chu Văn An, contact immediately:

- Phone: 0904 99 88 77

- Email: kd@etinco.vn

- Northern Office: 33 BT5, Phap Van – Tu Hiep new urban area, Yen So, Hanoi

- Southern Office: No. 19 Ly Van Phuc, Tan Dinh, Ho Chi Minh City

Frequently asked questions about multi-core electrical wires

Question 1: Is single-core wire or multi-core wire safer?

Reply: In fact, any type of electrical wire poses a potential electrical safety hazard if not connected and used properly. However, considering the structure, multi-core electric wires have separate insulation for each core, increasing the insulation ability of the wire. Along with that, having multiple cores also allows for tighter electrical connections, minimizing the risk of open circuits and short circuits.

Question 2: Does multi-core or single-core electrical wire have higher mechanical strength?

Reply: Multi-core electrical wires contain many soft copper or aluminum strands so they are easy to bend and twist. Compared with single-core wires, which are stiffer, difficult to bend or easily broken when bent many times, multi-core wires have higher mechanical strength.

Above, we have introduced to you general information about multi-core electrical wires. Although there are many advantages compared to single-core electrical wires, you should consider the suitability for the system, installation environment and budget before choosing electrical cables.

Other knowledge about electric cables, you can learn at: https://etinco.vn/tin-tuc/kien-thuc/kien-thuc-day-cap-dien/

Nội dung được phát triển bởi đội ngũ truongchuvananhue.edu.vn với mục đích chia sẻ và tăng trải nghiệm khách hàng. Mọi ý kiến đóng góp xin vui lòng liên hệ tổng đài chăm sóc: 1900 0000 hoặc email: hotro@truongchuvananhue.edu.vn