Nội dung bài viết

Industrial electrical cabinets are commonly used in factories, plants, commercial centers, etc. to perform the function of distributing electricity and controlling and protecting devices in electrical circuits. Corresponding to each different electrical system, there will be different types of electrical cabinets. In this article, we will mention the most common types of industrial electrical cabinets today.

Characteristics of industrial electrical cabinets

Industrial electrical cabinets have 3 main characteristics including: large capacity, sturdy design and specialized functions.

- Standard voltage level: Industrial electrical cabinets operate at standard industrial voltage level of 380V (Vietnam standard) and handle very large currents, up to thousands of Ampere.

- Large Size: Because it contains many operating devices and high-capacity loads, industrial electrical cabinets are often larger in size than residential electrical cabinets.

- Protection level: Industrial electrical cabinets require strict protection levels, usually IP54 or higher (anti-dust and resistant to water sprayed from all directions). For cabinets installed in harsh environments (too high, too low temperatures, chemicals, strong vibrations), the required IP level will be higher.

- Specialized design: This type of electrical cabinet is designed as a module, with separate compartments and compartments to install large capacity equipment and complex cable systems and signal transmission lines.

- Applications in many different environments: Such as factories, workshops, large industrial parks, public buildings, commercial centers…

Types of industrial electrical cabinets

There are many types of industrial electrical cabinets on the market, but we divide them into 11 most popular types.

General distribution cabinet (MSB)

Main Distribution Switchboard (MSB) is the most important type of electrical cabinet in the power distribution system of civil, commercial or industrial projects. This is where power is received from the grid or generator, then distributed to branch cabinets and large capacity loads in the system. MSB cabinets are often installed right behind low voltage transformer stations (from 15kV to 380VAC) and in front of the main MDB distribution cabinet with a rated current of up to 6,300A.

MSB cabinets are designed according to standards IEC 60439-1, IEC 60529 with many compartments and compartments, forming a scientific distribution system including access compartments, segment compartments and distribution compartments. In particular, the cabinet lid, sides and back of the cabinet can all be easily removed to facilitate installation, repair and maintenance when necessary. Gray, black, silver or red orange are the typical colors of MSB cabinets.

Main functions of MSB distribution cabinets:

- Receive main power from the grid and distribute it appropriately to load branches and power consumption areas.

- Turn off and on power, safely protect the entire load system against short circuits, overloads, and phase loss.

- Monitor important parameters such as current, voltage, capacity… to ensure stable and continuous operation of the transmission system.

- Connect to the ATS power adapter to convert mains power and backup power in case the main power source fails.

Main distribution cabinet (MDB)

The main distribution board MDB (Main Distribution Board) plays an intermediary role in the low voltage power system, taking on the task of taking power from the MSB main board to distribute to the loads. Therefore, MDB cabinets are often placed after the MSB main cabinet and in front of the DB branch cabinets.

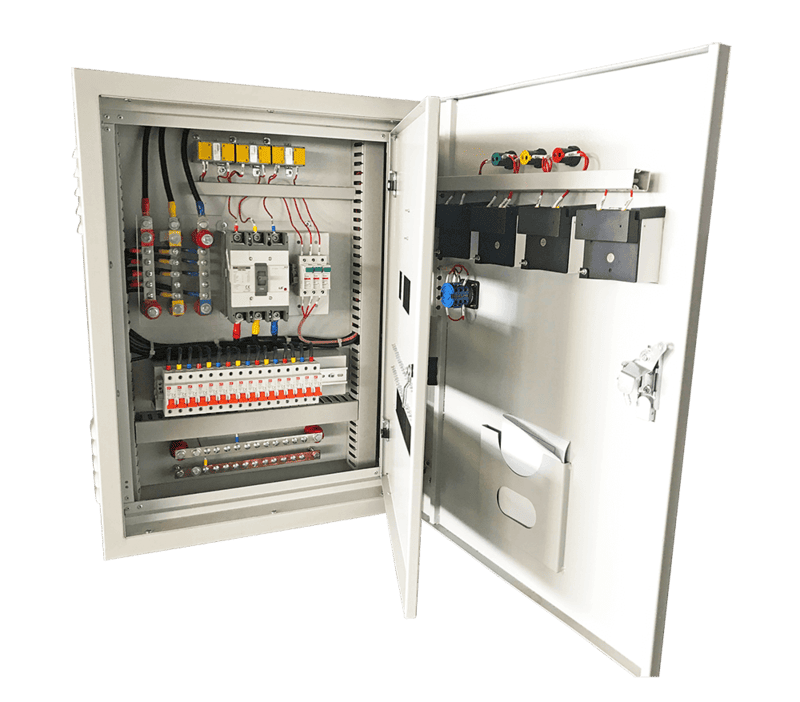

MDB electrical cabinets have a sturdy structure with a galvanized steel shell and an electrostatically sprayed exterior. The inside of the cabinet is divided into many compartments with specialized functions: compartment containing main protection device ACB/MCCB, compartment containing load protection device MCB/MCCB, compartment containing contactor, relay, compartment containing capacitors…

The main distribution cabinet is designed to support and protect the motor against overload, so this type of cabinet is commonly installed in factories in the mechanical field.

Branch distribution cabinet (DB)

The DB electrical panel (Distribution Board) is responsible for taking electricity from the main distribution panel and providing it to an area in the building, a certain system (lighting system, pumping system…) or consuming loads (sockets, machinery, industrial equipment).

To facilitate installation and maintenance, DB cabinets are divided into 3 colors: blue, red and yellow. Due to its compact size, branch distribution cabinets often have few equipment, of which some required equipment include: MCB/MCCB, phase indicator lights, fuses. Depending on needs, some DB electrical cabinets will be installed with ammeters, measuring meters or reactive power capacitors.

Motor control cabinet (MCC)

MCC motor control cabinet (Motor Control Center), also known as central control cabinet, is a specialized cabinet to control, monitor and protect electric motors in water pumping systems, wastewater treatment, HVAC, conveyors, cranes…

This type of cabinet can control one or more motors at the same time, supporting starting methods such as direct start, star – delta, inverter, soft start, thanks to a series of complex equipment including: PLC controller, ACB/MCCB switchgear, contactor, relay, inverter, soft starter.

The motor control cabinet is installed permanently or flexibly moved depending on the user’s needs, with 2 operating mechanisms as follows:

- Operate locally or remotely control to turn on and off and reverse the direction of motor rotation.

- Local operation or remote control to change motor rotation speed.

Lighting control cabinet

The lighting control cabinet has the ability to automatically turn on/off lights in real time or alternately turn on/off light bulbs in public areas (streets, parks, urban areas) or in factories, warehouses, shopping centers, office buildings, hospitals, stadiums… to save energy and protect the lighting system from electrical incidents.

There are 3 types of lighting cabinets including:

- PLC lighting electrical cabinet: Thanks to the integrated programmable controller (PLC) inside, the PLC lighting cabinet can change seasonal lighting modes or set multiple lighting modes for different times and capacities. The PLC cabinet has the ability to control light clusters with many modes, so it can be used to control lights during light festivals. In addition, PLC control cabinets can also control machines, systems, and production lines automatically based on programmed software.

- Timer lighting cabinet: This electrical cabinet uses a Timer to set the light on/off time, often used for garden or street lighting projects. Timer cabinets are simple to operate and cost-effective, but cannot perform remote monitoring and control.

- Communication lighting electrical cabinet: The most advanced type of lighting cabinet today when equipped with monitoring software, central control PLC and modern communication modules. It is also possible to turn on/off lights, but this electrical cabinet allows remote control via the app. However, the investment cost for communication lighting cabinets is quite expensive.

RMU cabinet

RMU cabinet (Ring Main Unit) is a closed medium voltage switchgear, integrating many functions such as on/off, measurement and quick fault isolation to protect the ring network distribution system. The RMU is designed with a metal enclosed structure, SF6 gas insulation, operating at medium voltage levels up to 36kV 630A.

The RMU cabinet is divided into separate compartments containing many switching and protective devices such as circuit breakers, disconnectors, relays, and fuses to help immediately isolate the fault on the circuit from the remaining parts, to prevent the faulty part from spreading. Therefore, RMU cabinets are an indispensable part in distribution stations, switching stations from medium voltage grids, or in large projects such as hotels, shopping centers, apartment buildings, industrial parks, hospitals, ports…

Firefighting electrical cabinet

Fire protection electrical cabinets (Fire protection electrical cabinets) are mandatory equipment in all projects, all fields, from households to civil, commercial, and industrial projects.

Electrical cabinet fire suppression is designed to operate according to a unified process: If the fire protection system leaks water or has a problem with the water source, the cabinet will automatically operate the pressure compensation pump. When there is a fire, the fire alarm sensor immediately operates and transmits a signal to the cabinet to operate the main pump. In case of power outage or main pump failure, the electrical cabinet automatically operates the necessary fuel pump. The fire protection electrical cabinet also has an automatic charging mechanism and notifies the battery’s full charge status.

ATS power switching cabinet

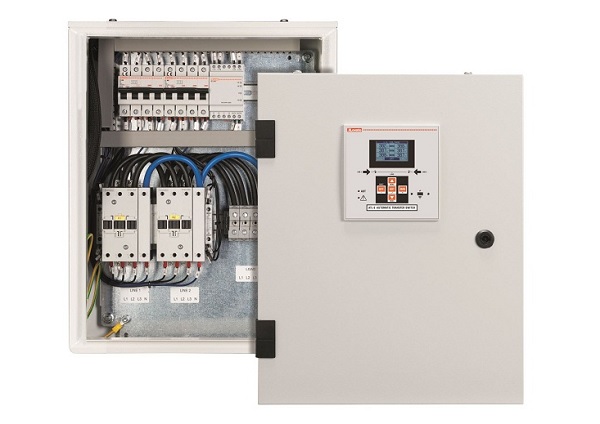

ATS (Automatic Transfer Switches) electrical cabinets are often installed in applications that require loads to be continuously powered such as hospitals, data centers… to help automatically switch power sources between the main source and backup sources in case the mains source fails.

The ATS power switch operates based on the main source priority principle, meaning that in all conditions, unless the main source has a problem, the ATS will always be in the mode to let the mains power pass through. When the main power source loses power, the ATS cabinet automatically switches to the backup source (possibly a generator) to minimize power interruption.

Important parameters of ATS cabinet:

- Rated Voltage: 380V/415V

- Rated current: 1600A/2000A/2500A/3200A/6300A

- Switching time: 5-10s

Power switching cabinets are often divided into 3 types including:

- 1 mains power source, 1 backup power source

- 2 mains power sources, 1 backup power source

- 1 mains power source, 2 backup generator sources.

Capacitor cabinet

Capacitor cabinets include many capacitors connected in parallel with the load, helping to increase the cosφ coefficient, reduce reactive power, thereby reducing power consumption as well as fines from Electricity at factories, plants, and production lines.

This type of cabinet is quite commonly installed in low voltage electrical networks, especially when the system uses many loads with high inductance and resistance. The capacitor bank should be located in a separate technical room with some mandatory equipment such as: capacitor, capacitor controller, circuit breaker, contactor, indicator lights, and meters.

Electric meter cabinet

Electric meter cabinets have the function of measuring and monitoring technical or commercial electricity for households, electricity consuming units or Electricity units. This electrical cabinet is easy to find in transformer stations, factories, offices, apartments… with many different capacities depending on the load (single-phase load or 3-phase load).

- With high capacity 3P load (>100A): It is recommended to use an indirect meter combined with a 1A or 5A secondary current transformer.

- With small capacity 3P load (Can use direct meter 10/20A, 10/40A, 20/40A,…

- With 1P load: Most use 1P meters directly 3/9A, 5/20A, 10/40A.

Synchronous electrical cabinets

Synchronizing Panel is designed to connect generators or independently operating power sources that can work together in parallel. Accordingly, when the grid power source has a problem, 2 or more generators in the system will automatically start, synchronize and share the load with each other. Besides, the cabinet also has the function of monitoring the load and deciding the number of generators to operate according to the specific needs of the load.

Synchronous air conditioner cabinets are often divided into many compartments, including 1 main control compartment for the mains source and independent control compartments for each generator. The cabinet supports two operating modes: automatic and manual, and also integrates warning and monitoring functions on the LCD screen, indicator lights, and loudspeakers.

Questions about industrial electrical cabinets

Question 1: To compensate for reactive power and reduce electricity fines, what type of electrical cabinet should be installed?

Reply: In this case, a capacitor bank should be installed to improve the cosφ coefficient, thereby improving power quality.

Question 2: Are fire protection electrical cabinets required to be installed in all projects?

Reply: Have. Fire and explosion safety is a basic condition in every project. Therefore, it is necessary to equip fire protection systems in all projects from civil, commercial to industrial.

Nội dung được phát triển bởi đội ngũ truongchuvananhue.edu.vn với mục đích chia sẻ và tăng trải nghiệm khách hàng. Mọi ý kiến đóng góp xin vui lòng liên hệ tổng đài chăm sóc: 1900 0000 hoặc email: hotro@truongchuvananhue.edu.vn