Nội dung bài viết

Electrical cabinets are places that contain electrical equipment and components necessary to operate, monitor and protect an electrical system. Therefore, properly installing electrical cabinets is a mandatory factor to ensure that activities inside the electrical cabinet take place properly and safely. Below are instructions on how to install industrial electrical cabinets according to standards from Trường Chu Văn An.

Standards on how to install electrical cabinets

Most industrial electrical cabinets operate at high voltage, large current, and contain many complex devices and components. Therefore, the installation of industrial electrical cabinets must comply with international standards and specific national standards as follows:

- TCVN 7994-1:2009 (IEC 60439-1:2004): General standards apply to low-voltage switchgear and control cabinets, focusing on technical requirements, design and testing for electrical cabinets at the manufacturing plant.

- IEC 60520 (TCVN 4255:2008): The standard regulates the protection level of the outer shell (IP level) of electrical cabinets, indicating the dust and water intrusion resistance of the cabinet shell, depending on the operating environment.

- TCVN 6223:2016: The standard stipulates technical requirements for control cabinets and centralized control, including standards for size, corrosion protection, explosion protection, etc.

- IEC 60947 (TCVN 6592): The standard applies to low-voltage switching and control devices such as circuit breakers, contactors, relays, inverters, etc. installed inside electrical cabinets.

- TCVN 6669:2001: Standards for current protection devices in industrial electrical systems, including standards for load, insulation, and mechanical durability.

- Standards for preserving electrical cabinets: During transportation and storage, the electrical cabinet needs to be maintained at a storage temperature of 25 ºC to +55 ºC and no more than 24 hours at +70 ºC.

Instructions on how to install electrical cabinets

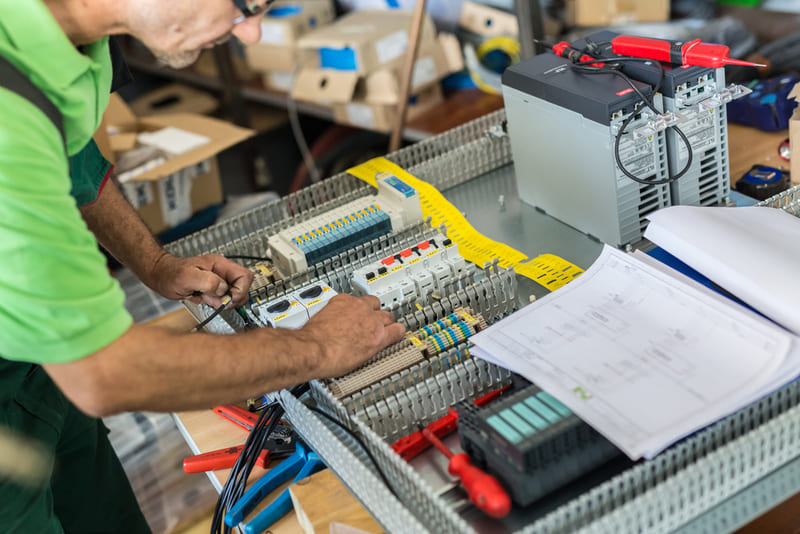

Similar to the industrial electrical cabinet design process, the electrical cabinet installation process also has strict logic between stages, requiring the implementer to have highly specialized knowledge, clearly understand the electrical cabinet principle diagram and technical and electrical safety standards.

How to install a standard electrical cabinet usually goes through 8 steps as follows.

Read design drawings and prepare complete equipment

Design drawings are an important basis for engineers to have the most general view of the layout, size and operating principles of electrical cabinets, as well as the list, quantity and location of important equipment and components inside. Therefore, design drawings must be accurate, optimize investment costs, limit electromagnetic interference between devices, while ensuring aesthetics during installation and the ability to expand the system in the future without needing to replace the cabinet.

The process of reading design drawings requires mastering:

- Panel specifications: Includes panel classification, parameters, models and standards.

- Electrical symbols: Most electrical symbols have been conventioned according to international standards, however some manufacturers may have different symbols for some specific devices.

- Device layout: Determine the location, installation method and actual size of equipment and components inside the cabinet. In addition to the main equipment, it is necessary to accurately determine the types of bolts, mounting rails, electrical trays, and ecu to connect the equipment to the electrical cabinet.

- Principle diagram: Shows how the electrical devices in the cabinet interact and connect with each other, helping engineers understand the operating principles of the electrical cabinet.

- Motive drawing: Helps determine the location of main busbars, power wires, power terminals as well as the quantity and characteristics of main conductor groups.

- Control chart: It is responsible for determining whether the electrical cabinet is operating properly or not, and can detect potential risks early when the electrical cabinet is in operation.

In addition, it is necessary to fully prepare materials, equipment, machinery, and support tools to facilitate the assembly of electrical cabinets, including:

- Main equipment: Such as switching, control, protection equipment… These devices need to be of the correct type and specifications shown in the technical drawings.

- Electrical cabinet cover: The selection of electrical cabinet enclosures needs to ensure strict requirements on size, protection level (IP) according to the installation environment, cabinet material, and electrical cabinet form.

- Connection materials: Main busbar, power cable, control cable, cosse head,…

- Support tools: Electric meter, electric pliers or other supporting machinery.

Place the device mounting bracket on the cabinet

Equipment brackets in cabinets are installed according to general principles: If there is a design, the brackets need to comply with the correct size and position as required by the design.

If there is no design, the mounting location needs to meet the requirements: minimizing installation area, saving wires and ensuring aesthetics. How to properly arrange equipment on racks can be referred to:

- The master circuit breaker is located in the upper left corner of the cabinet.

- The fuse, power supply, and phase protector are located in the upper right corner of the cabinet.

- The branch circuit breaker is placed in the bottom row, followed by the controller, intermediate relay, contactor, and thermal relay. Control equipment is usually placed on the same side, avoiding the same group as power equipment.

- The player is in last place.

Label equipment in electrical cabinets

This labeling takes the design drawing as the basis, to help engineers easily make connections without having to check the drawings and count the number of equipment many times. Make sure the font size and size of the sticker is appropriate for each electrical device.

Proceed to assemble the copper busbar

For distribution cabinets with rated current of the total circuit breaker

On the contrary, for electrical cabinets with rated current of the total circuit > 100A, copper busbars will be used to connect the circuit.

The busbar processing stage needs to comply with the parameters specified in the technical drawings. Busbar can be plated with tin or nickel to increase durability and conductivity. Busbars should be covered with heat-shrinkable PVC or epoxy paint to easily identify each type by color. The process of tightening the busbar to the support with bolts also needs to be done correctly so as not to affect the transmission capacity. Finally, additional mica shielding should be equipped to protect the busbar and insulate users.

Connect the electrical cabinet

This is an extremely important step to ensure continuity of the electrical cabinet.

- It is required that all connections in the electrical cabinet need to be made accurately, complying with the design drawings.

- Clearly distinguish between phases by identification color, with specific notes on the bridges to facilitate repair and maintenance.

- The control circuit and power circuit must be connected far apart or wired perpendicularly to avoid signal interference with sensors or sensors.

- Connect sequentially from the power circuit to the control circuit.

- Signal wires need to be equipped with an anti-interference shield. Signal wires often use wires with small cross-sections from 0.5 – 1.5mm2.

Comprehensive inspection of electrical cabinets

The process of checking the electrical cabinet after complete assembly goes through two stages: checking for no power and checking for power supply.

The electrical failure check process for the entire electrical cabinet includes the following steps:

- Check the position of bus bars, power wires, and control wires according to the principle diagram and wiring diagram.

- Check the equipment and wiring routing labels.

- Check connections, cosse ends and terminals.

- Check insulation of wires, busbars and overall electrical cabinet.

- Remove tools and obstructions left inside the electrical cabinet.

- Connect the enclosure to the grounding system to ensure safety.

After the no-power test is completed, the electrical cabinet needs to be energized for test operation according to these steps:

- Check insulation between phases and between phases and ground wire.

- Check the input voltage of the cabinet and the operation of the indicator lights.

- Set parameters for control devices such as thermal relays, time relays, HMI.

- Turn on the total and branch circuits and measure the voltage behind the branch circuits.

- Test the electrical cabinet under loaded and unloaded conditions to check the condition of the equipment during operation.

Clean the electrical cabinet and check for acceptance

After completing the inspection process, the electrical cabinet needs to be cleaned before being transported to the installation area. You should use a vacuum cleaner and brush to remove dust, iron filings, electrical cable core shells, and excess details inside and outside the electrical cabinet.

The electrical cabinet will then be covered to prevent scratches and impacts and transported to the place of operation.

Important notes on how to install electrical cabinets

Installing electrical cabinets is a job that requires high expertise and technique, requiring meticulousness, care and responsibility from the implementer. This not only protects the system against electrochemical problems but also ensures user safety. Here are some important notes on how to install electrical cabinets.

About installation location

- Away from heat and moisture sources: Electrical cabinets should be placed in a dry location, away from sources of moisture and heat to protect the equipment inside. In case the electrical cabinet must be installed in humid areas, extreme temperatures or near chemical sources, it is necessary to choose an electrical cabinet with a high IP protection level and take measures to isolate the electrical cabinet from these factors.

- Installation space: Make sure the electrical cabinet has no obstructions in front and behind the cabinet to facilitate the inspection, repair and maintenance process, especially in case of an emergency.

About how to choose electrical cabinets

- Type of electrical cabinet: Electrical cabinets need to be suitable for the specific characteristics of the installation environment and specific application.

- Protection level: The IP protection level of the electrical cabinet must meet the requirements for protection against dust and water penetrating from many sides. Usually outdoor electrical cabinets will have a higher IP level than indoor electrical cabinets.

- Protection measures: Electrical cabinets need to be fully equipped with protection measures such as overload, overcurrent, overvoltage, phase loss, grounding, and lightning protection to maintain the stability and continuity of the electrical system.

About the wire

- Neatly arranged: Wires need to be neatly arranged in pipes or ladders to avoid confusion of power wires, control wires, and signal wires, which can easily cause electromagnetic interference and make repairs and maintenance difficult.

- Full labeling: Make sure all wires, circuits and equipment in the cabinet are clearly labeled and marked.

Regarding inspection, testing and periodic maintenance

- Electrical cabinet installation needs to be done in accordance with international and national technical standards and comply with the original technical drawings.

- Electrical cabinets need to be periodically maintained and inspected to detect potential problems early and fix them promptly.

Some questions about how to install electrical cabinets

Question 1: Why is it necessary to read design drawings carefully before installing electrical cabinets?

Reply: Technical drawings show the most general information about the electrical cabinet, including: quantity, equipment installation location, internal structure of the electrical cabinet, principle diagram… which is very necessary for engineers to carry out the installation according to the correct technique and requirements.

Question 2: Does the electrical cabinet need trial operation before handover?

Reply: Have. All electrical cabinets must be tested before being transported to the installation area. This step helps engineers determine the operating status of the cabinet, detect problems during operation and prepare timely replacement and repair plans. Electrical cabinets can be tested with and without load to fully evaluate actual operating capabilities.

Above, Trường Chu Văn An has guided you on how to properly install industrial electrical cabinets. Hope you are satisfied with this knowledge. Other information related to electrical cabinets, you can find out at: https://etinco.vn/tin-tuc/kien-thuc/kien-thuc-tu-dien/

Nội dung được phát triển bởi đội ngũ truongchuvananhue.edu.vn với mục đích chia sẻ và tăng trải nghiệm khách hàng. Mọi ý kiến đóng góp xin vui lòng liên hệ tổng đài chăm sóc: 1900 0000 hoặc email: hotro@truongchuvananhue.edu.vn